CALB e sa sisinyeheng

CALB ha e khone ho sisinyeha ka ho khabisoa ka 'mele holim'a resin e phahameng ea hydrophobic e leng macroporous, styrene / methacrylate polymer.Immobilized CALB e loketse lits'ebetso tsa lihlapolli tsa tlhaho le lits'ebetso tse se nang solvent, 'me e ka sebelisoa hape le ho sebelisoa hape ka makhetlo a mangata maemong a loketseng.

Khoutu ea Sehlahisoa: SZ-CALB- IMMO100A, SZ-CALB- IMMO100B.

★Ketso e phahameng, khetho e phahameng ea chiral le botsitso bo phahameng.

★Ts'ebetso e betere maemong a se nang metsi.

★Tlosa habonolo tsamaisong ea lintho, felisa maikutlo ka potlako, 'me u qobe masala a protheine sehlahiswang.

★E ka sebelisoa hape le ho sebelisoa hape ho fokotsa litšenyehelo.

| Ketsahalo | ≥10000PLU/g |

| pH e fapaneng bakeng sa karabelo | 5-9 |

| Boemo ba mocheso bakeng sa maikutlo | 10-60 ℃ |

| Ponahalo | CALB-IMMO100-A: Bosehla bo bobebe ho isa ho bosootho bo tiileng CALB-IMMO100-B: Bosoeu ho isa bosootho bo bobebe |

| Boholo ba likaroloana | 300-500μm |

| Tahlehelo ha o omisa ho 105 ℃ | 0.5%-3.0% |

| Resin bakeng sa immobilization | Macroporous, styrene / methacrylate polymer |

| Reaction solvent | Metsi, organic solvent, joalo-joalo, kapa ntle le solvent.Bakeng sa karabelo ho li-solvents tse ling, metsi a 3% a ka eketsoa ho ntlafatsa phello ea karabelo |

| Boholo ba likaroloana | CALB-IMMO100-A: 200-800 μm CALB-IMMO100-B: 400-1200 μm |

Tlhaloso ea yuniti: yuniti e le 'ngoe e lumellana le motsoako oa 1μmol ka motsotso propyl laurate ho tloha lauric acid le 1-propanol ho 60 ℃.Lintlha tse ka holimo tsa CALB-IMMP100-A le CALB-IMMO100-B li lumellana le bajari ba immobilized ba nang le boholo bo fapaneng ba likaroloana.

1. Mofuta oa reactor

Enzyme e sa tsamaeeng e sebetsa ho ka bobeli kettle batch reactor le bethe e tsitsitseng e tsoelang pele ea ho phalla.Hoa lokela ho hlokomeloa ho qoba ho senya ka lebaka la matla a ka ntle nakong ea ho fepa kapa ho tlatsa.

2. Ho arabela pH, mocheso le solvent

Enzyme e sa tsamaeeng e lokela ho eketsoa qetellong, ka mor'a hore lisebelisoa tse ling li kenngoe le ho qhibiliha, 'me pH e lokisoe.

Haeba tšebeliso ea substrate kapa sebopeho sa sehlahisoa se lebisa phetohong ea pH nakong ea karabelo, buffer e lekaneng e lokela ho eketsoa tsamaisong ea karabelo, kapa pH e lokela ho beoa leihlo le ho lokisoa nakong ea karabelo.

Ka har'a maemo a mamello a mocheso a CALB (ka tlase ho 60 ℃), sekhahla sa phetoho se eketsehile ka ho eketseha ha mocheso.Ka ts'ebeliso e sebetsang, mocheso oa karabelo o lokela ho khethoa ho latela botsitso ba substrate kapa sehlahisoa.

Ka kakaretso, ester hydrolysis reaction e loketse tsamaisong ea metsi, athe ester synthesis reaction e loketse tsamaisong ea organic phase.Mokelikeli oa tlhaho o ka ba ethanol, tetrahydrofuran, n-hexane, n-heptane le toluene, kapa motsoako o tsoakiloeng o loketseng.Bakeng sa karabelo ho li-solvents tse ling, metsi a 3% a ka eketsoa ho ntlafatsa phello ea karabelo.

3. Tšebeliso hape le bophelo ba ts'ebeletso ea CALB

Tlas'a boemo bo nepahetseng ba karabelo, CALB e ka khutlisoa le ho sebelisoa hape, 'me linako tse ikhethileng tsa ts'ebeliso li fapana ho ea ka merero e fapaneng.

Haeba CALB e fumanweng e sa sebediswa hape kamehla mme e hloka ho bolokwa ka mora ho fola, e hloka ho hlatsuwa le ho omiswa le ho kwalwa ka mocheso wa 2-8 ℃.

Kamora ho sebelisoa hape ka makhetlo a 'maloa, haeba ts'ebetso ea karabelo e fokotsehile hanyane, CALB e ka eketsoa ka nepo 'me ea tsoela pele ho sebelisoa.Haeba ts'ebetso ea karabelo e fokotsehile haholo, e hloka ho nkeloa sebaka.

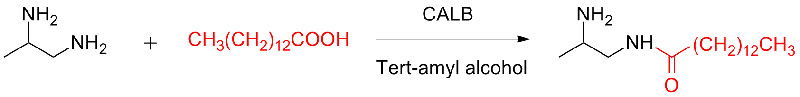

Mohlala 1(Aminolysis)(1):

Mohlala 2(Aminolysis)(2):

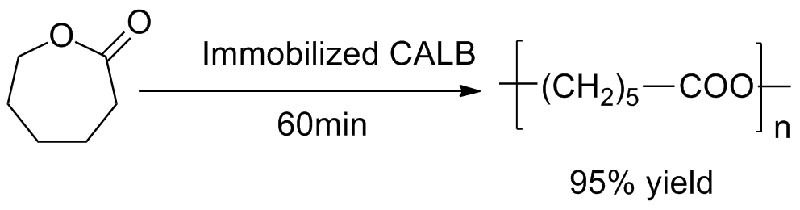

Mohlala 3(Lesale la ho bula polyester synthesis)(3):

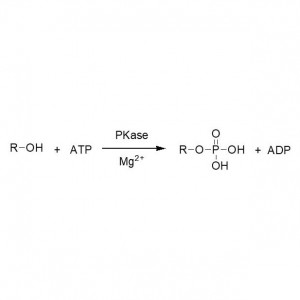

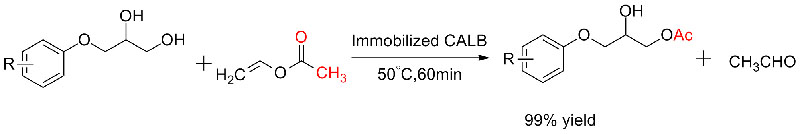

Mohlala 4(Transesterification, regioselective of hydroxyl group)(4):

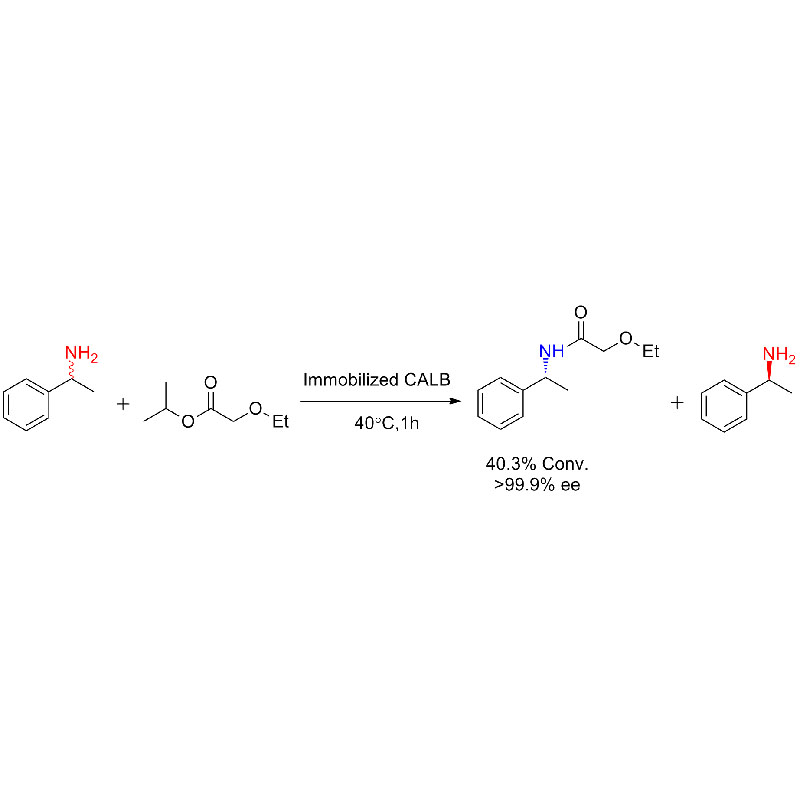

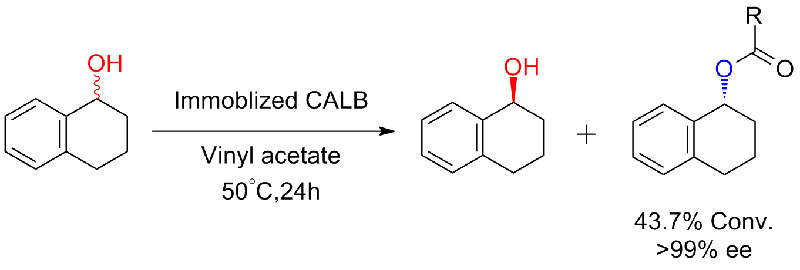

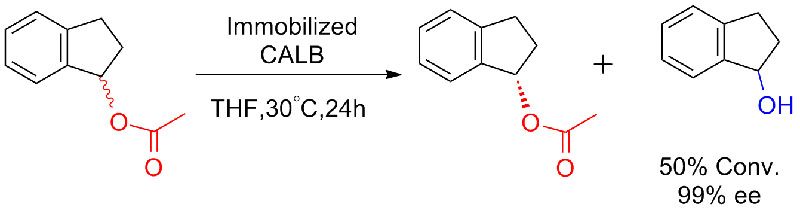

Mohlala 5(Transesterification, tharollo ea kinetic ea lino tse tahang tsa morabe)(5):

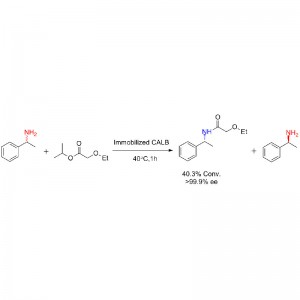

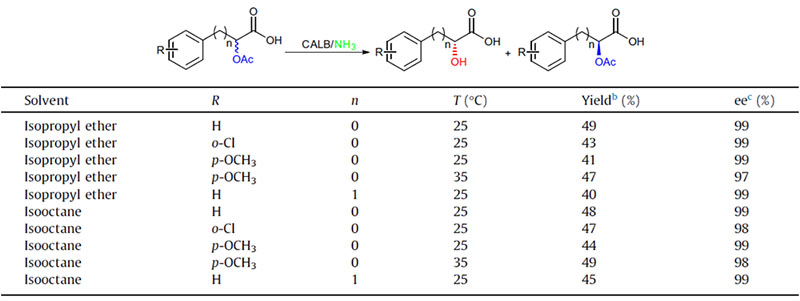

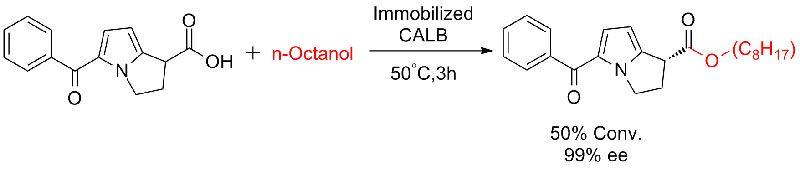

Mohlala 6(Esterification, kinetic resolution ea carboxylic acid)(6):

Mohlala 7(Esterlysis, kinetic resolution)(7):

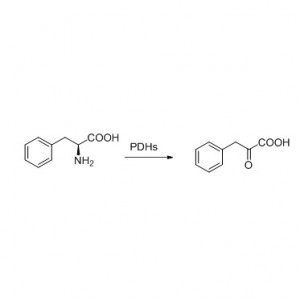

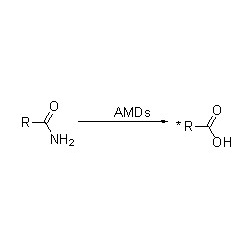

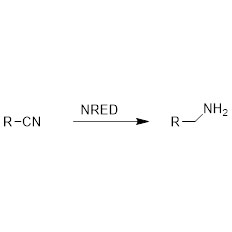

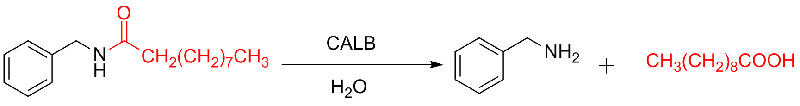

Mohlala 8(Hydrolysis of amides)(8):

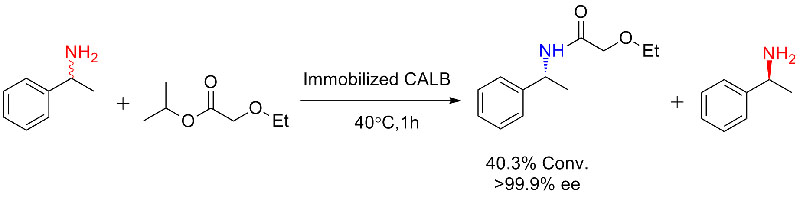

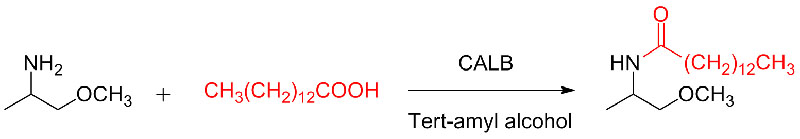

Mohlala 9(Acylation of amines)(9):

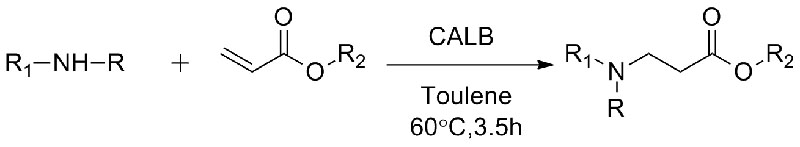

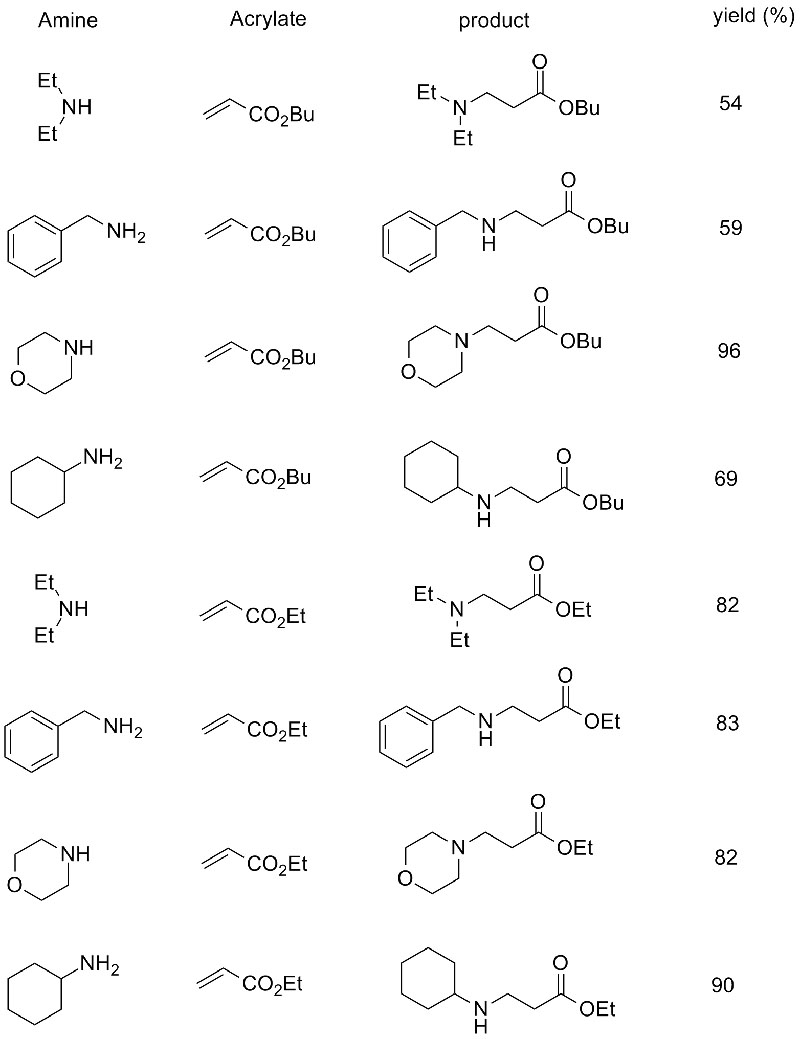

Mohlala 10(Aza-Michael addition reaction)(10):

1. Chen S, Liu F, Zhang K, e tal.Tetrahedron Lett, 2016, 57: 5312-5314.

2. Olah M, Boros Z, anszky GH, e tal.Tetrahedron, 2016, 72: 7249-7255.

3. Nakaoki1 T, Mei Y, Miller LM, e tal.Ind. Biotechnol, 2005, 1(2): 126-134.

4. Pawar SV, Yadav G DJ Ind. Eng.Chem, 2015, 31: 335-342.

5. Kamble MP, Shinde SD, Yadav G DJ Mol.Catal.B: Enzym, 2016, 132: 61-66.

6. Shinde SD, Yadav G D. Process Biochem, 2015, 50: 230-236.

7. Souza TC, Fonseca TS, Costa JA, e tal.J. Mol.Catal.B: Enzym, 2016, 130: 58-69.

8. Gavilian AT, Castillo E, Lopez-Mungu'AJ Mol.Catal.B: Enzym, 2006, 41: 136-140.

9. Joubioux FL, Henda YB, Bridiau N, e tal.J. Mol.Catal.B: Enzym, 2013, 85-86: 193-199.

10. Dhake KP, Tambade PJ, Singhal RS, e tal.Tetrahedron Lett, 2010, 51: 4455-4458.